Reconditioning Information

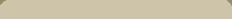

All air components are disassembled,

inspected and returned to original

specifications. Units have new seals,

gaskets, bearings, valves, etc. installed

in them for long lasting performance.

cartridges or new desiccant installed for

superior moisture absorption and are

purge tested. Dryer heaters are tested

for proper performance to avoid cold

weather freeze ups.

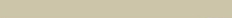

replaced with the proper piston and

piston rings to ensure the best air

compression possible, with the least

amount of oil bypass. They are water,

oil and air tested for leaks and

maximum performance.

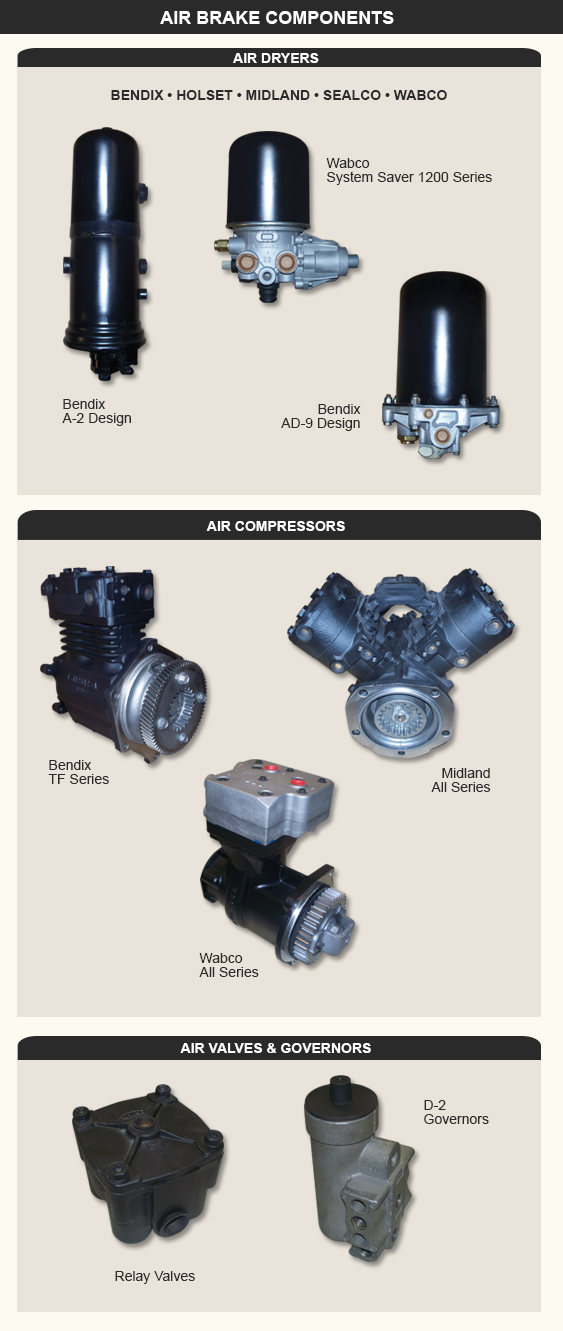

Additional core deposits must be paid

up front with the cost of the part.

Deposits will be refunded upon return

of refundable core (core must be the

same as unit purchased).

5836 W. 66th Street / Bedford Park, IL 60638

5836 W. 66th Street / Bedford Park, IL 60638